BRIEF DESCRIPTION OF THE TECHNOLOGY

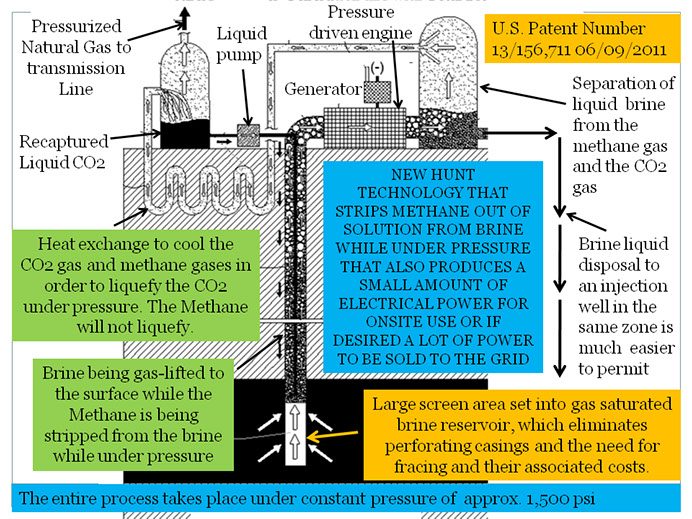

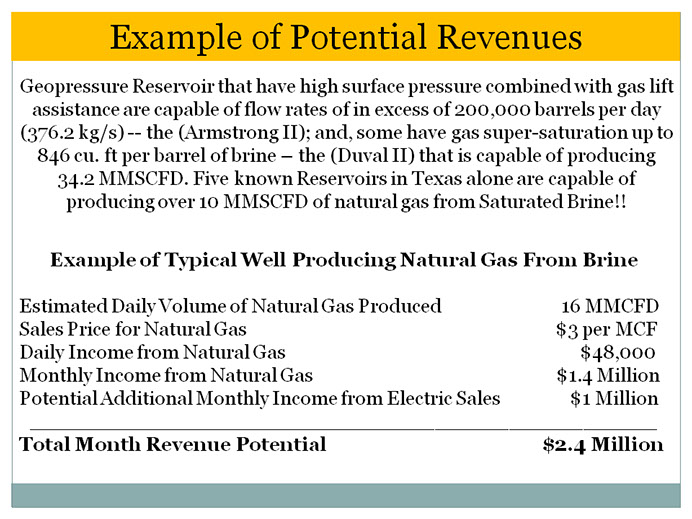

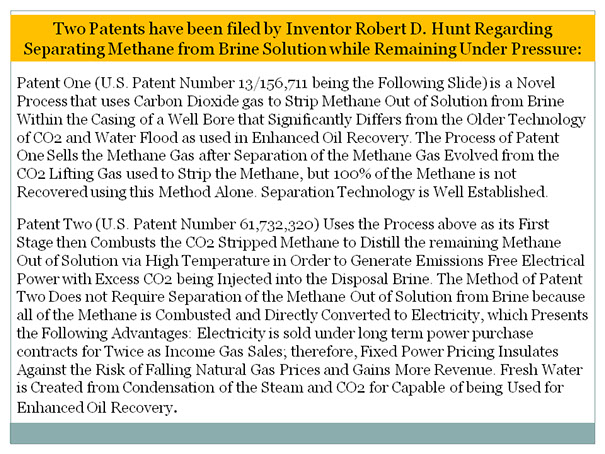

Inventor and Founder Robert Hunt has filed two innovative patents that are new cost effective technologies to harness the natural gas found within methane saturated formations that will be used by Satuated Gas, Inc. The first patent (U.S. Patent Number 13/156,711) focuses on producing natural gas that is sold and that is delivered to gas transmission pipe lines.

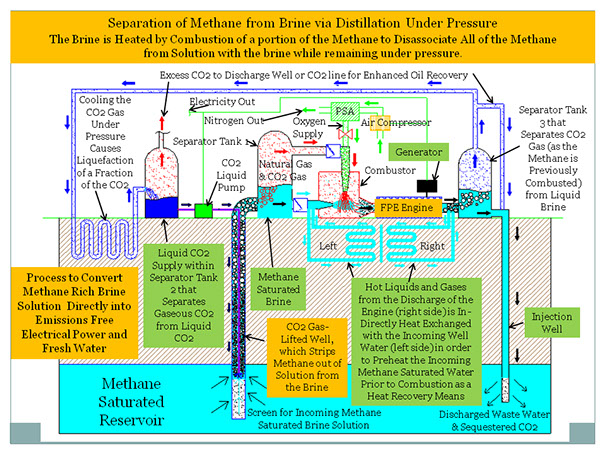

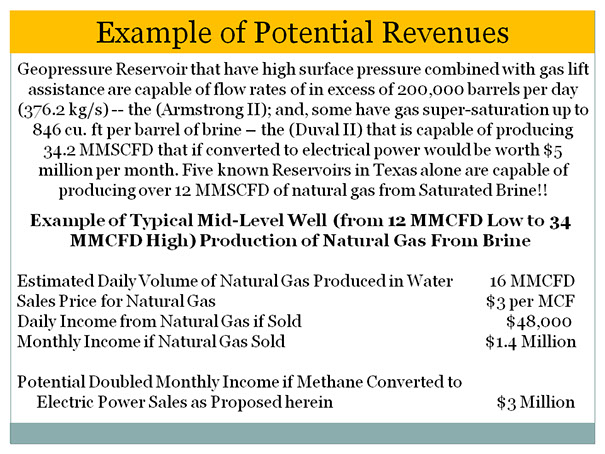

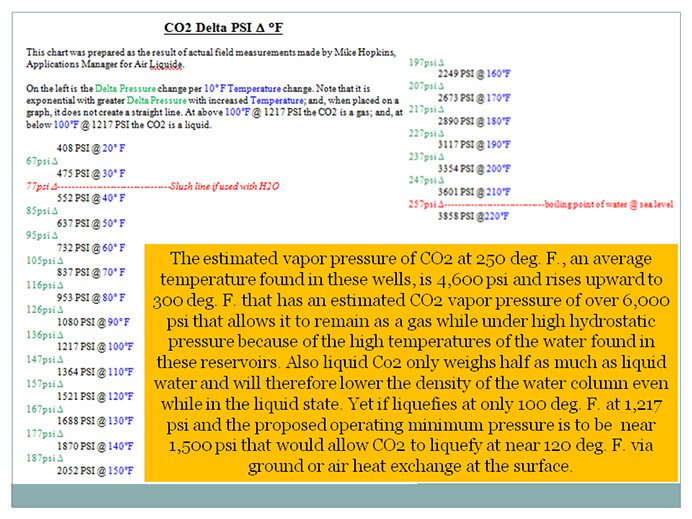

The second patent (U.S. Patent Number 61,732,320) takes the process a step further. After stripping methane from solution under pressure using CO2 as the stripping gas, the previously stripped natural gas is then combusted to heat the brine in order to distill any remaining natural gas out of solution in order to generate utility scale electrical power output. No natuaral gas is sold. The Income is derived from electricity sales.

Separation Under Pressure of Methane from Hot Brine Useful for Geothermal Power

(U.S. Patent Number 13/156,711)

Method to Convert Methane Saturated Brine into Emissions Free Electrical Power and Fresh Water

(U.S. Patent Number 61,732,320)

Click the First Slide to the Left to Begin the Slide Show;

and, then Click off Slide when Finished Viewing.

Click the First Slide to the Left to Begin the Slide Show;

and, then Click off Slide when Finished Viewing.

And, the process (U.S. Patent Number 61,732,320)produces pressurized steam that mixes with the high pressure water that is not vaporized, the heat expanded CO2 and other gases being the product of combustion to drive a free piston engine prime mover of his invention capable of being driven by this high pressure dual phase mixture in order to generate electrical power.

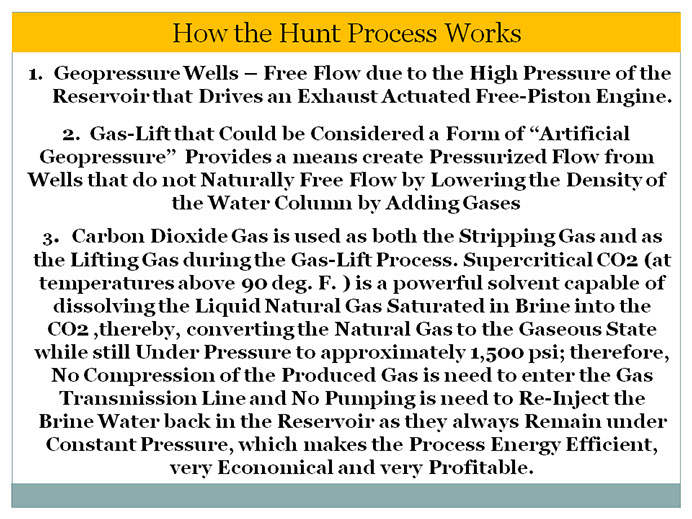

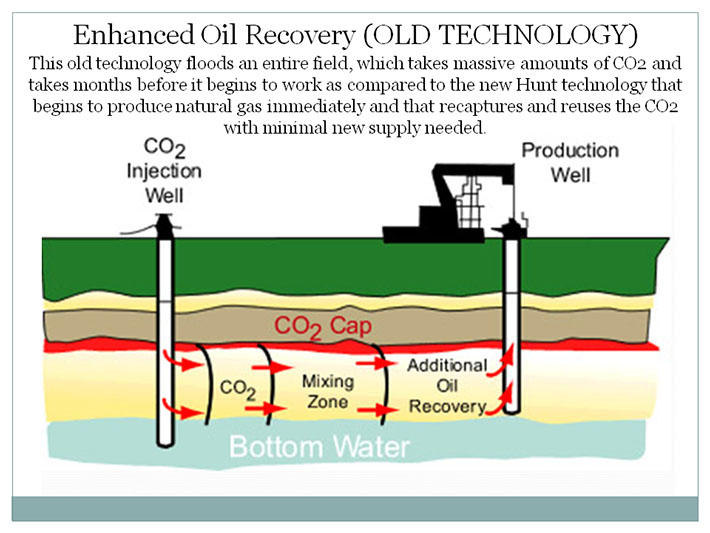

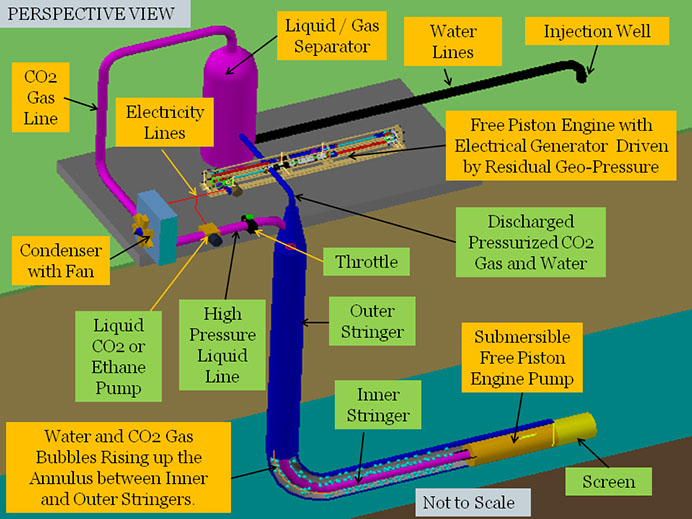

The process uses CO2 to strip methane from natural gas within an individual well while remaining under pressure, which is important because it localizes the process to a single well and then the discharge water and the natural gas produced remain under pressure to eliminate the need to pump water into an injection well and to compress natural gas to pressures required by the gas transmission line.

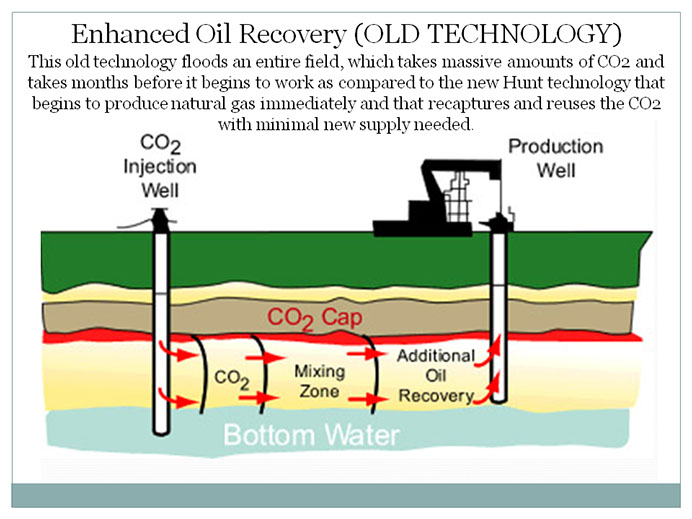

Excess CO2 is sequestered into the formation or alternatively is used to drive EOR projects. The process also produces fresh water when the steam is condensed that does not have to be sent to a disposal well and can be used as fresh frac water. The technology is so cost effective in the generation of electricity that it makes the process profitable and transcends the oil and gas business into the power generation business that is much more profitable than is selling natural gas at today's low prices by more than double. Saturated Gas, Inc. was formed to commercialize Mr. Hunt's technology.

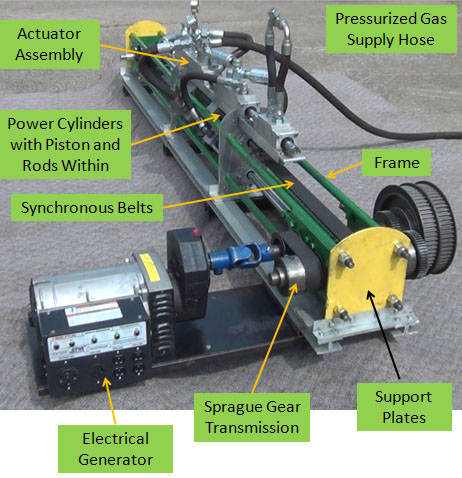

Free Piston Engine (FPE) Enabling Technology

The tremendous versitility and efficiency of the Free Piston Engine that was developed by Robert D. Hunt as an enabling technology to accomplish geothermal / oil and gas co-production is clearly shown below.

Pressure Driven Engine

FPE Gas Compressor

Perfect Power Transfer

Hybrid Natural Gas Vehicle

Submersible FPE

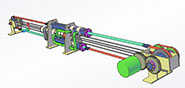

The patented free piston engine was developed to harness high pressure, dual phase fluid flow from a pressurized geothermal / oil and gas co-production well. The mechanical produced power can be used to pump liquids, compresses gas, and to generate electrical power, etc.

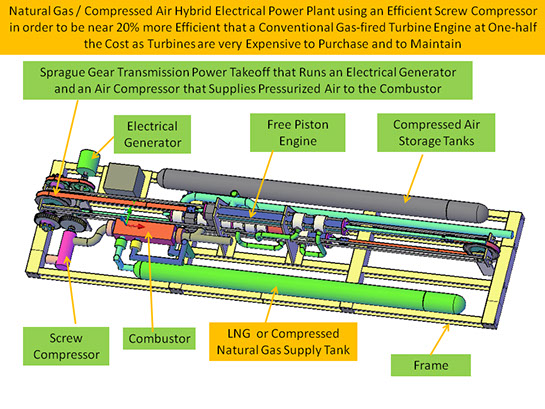

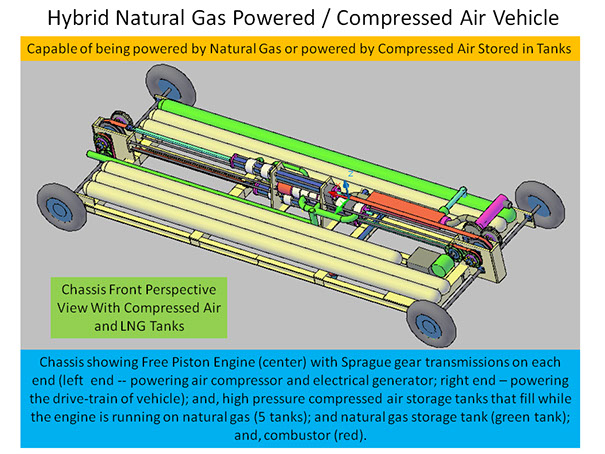

The Free Piston Engine may be configured as a Hybrid Natual Gas Fired or Compressed Air Powered Liquid Pump or Gas Compressor (shown above as a gas compressor). During operation on natural gas air is compressed and is stored in high pressure compressed air storage tanks.

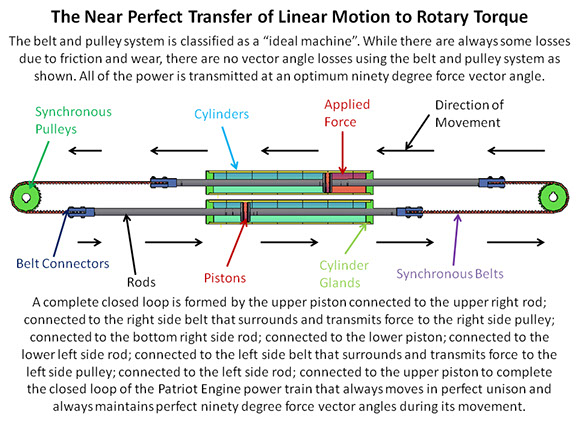

Conventional engines lose a lot of power produced by the pistons due to poor vector angles, mainly due to the use of crank shafts that can reduce the efficiency of power transfer very dramatically.

The Free Piston Engine accomplishes near perfect transfer of the reciprocating power output produced by the pistons as shown in the graphic to the left using a synchronous belt and synchronous pulley system.

A patented Sprague Gear Transmission converts the back and forth motion of the pistons and rods into rotation in a single direction (not shown) also always maintaining a perfect vector angle for maximum transfer of power.

Potential Uses for the Compressed Air / Natural Gas Powered Hybrid Free Piston Engine

A low emissions ship engine that can use compressed air while in or near the port; and,

A hydraulic engine for heavy equipment i. e. excavators and bulldozers that operate by hydraulic power being merely an engine that drives a high pressure hydraulic pump; and,

A natural gas compressor; and,

An electrical generator; and,

A gas-lift engine for oil and gas production that can additionally perform as an electrical generator, a natural gas compressor or provide hydraulic or pneumatic power take-off capable of operating a drilling rig among many other beneficial uses.

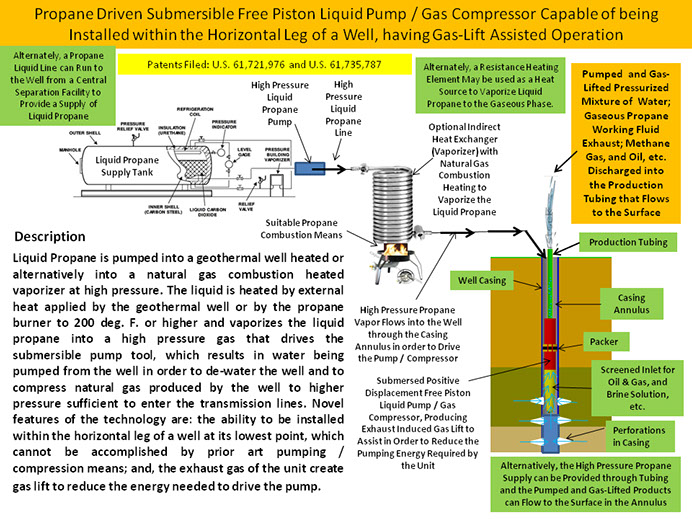

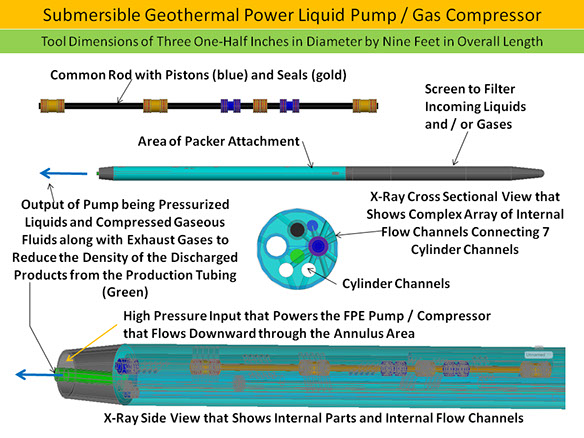

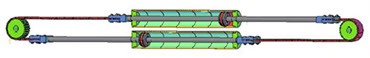

The present patent discloses a novel submersible liquid pump / gas compressor capable of being installed within the horizontal leg of an oil and gas well using conventional installation means and being capable of high force positive displacement liquid pumping and high pressure gas compression that works like no other prior art device known in that its exhaust gases are mixed with the products of the pumping and compression in order to lower the density of the mixture of liquids and gases in order to reduce the amount of energy input needed to drive the apparatus.

Furthermore, the heat of compression created during its operation is used to help heat and to vaporize the working fluid by indirect heat exchange as the liquid phase working fluid flows downward within the annulus of the well and the gases heated by the heat of compression flow upward within the production tubing, which increases the efficiency of the process substantially.

SEE ADDITIONAL INFORMATION IN THE SECTION IMMEDIATELY BELOW

Click the Link to the Right to View a Free Piston Engine Test Video on YouTube

Click the Link to the Right to View an Animation of Perfect Power Transfer Method of the FPE

Submerged Free Piston Engine Liquid Pump / Gas Compressor

One of the most novel uses of the Free Piston Engine is shown in the two slides above whereby the FPE is reduced in size to the approximate dimensions of a common gas lift mandrel in order to be submerged deep into the well to dewater the well being powered by geothermal heat energy as shown in the first slide.

Click to View Slides

However, the submerged FPE, which performs powerful positive displacement pumping, is many, many times more powerful than a gas-lift mandel or a hydraulicly powered Venturi style Jet Pump in its ability to pressurize liquids to the surface. And, it can pump or compress far greater volumes of fluids.

The unit is driven by high pressure gases generated by geothermal energy from a hot deep well. One of its novel features is that the exhaust gases from the engine are mixed with the pumps output in order to lower the density of the mixture that reduces the amount of energy needed to operate the unit substantially. Also the process increases the velocity of the fluid's movement to the surface.

The second slide shows that more powerful operation of the submerged FPE can be attained using higher temperature combustion to produce a more powerful working fluid to drive the engine. Propane is used because it is normally present within oil and gas wells and if not separated and reused at the well head, the cost of the propane is recovered as it is sold as a liquid. The option is to merely pump the liquid propane from the separator facility back to the individual wells to be used over and over again at no costs.

Our Logo Suitably is the Scientific Symbol for "Gas Saturation"